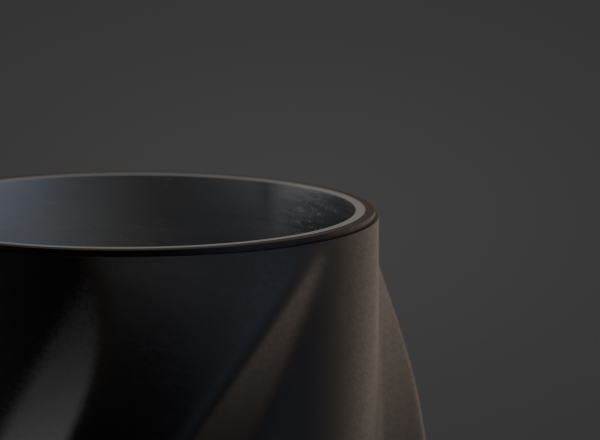

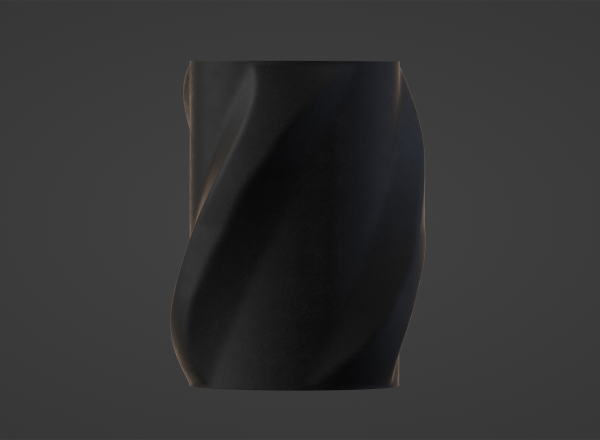

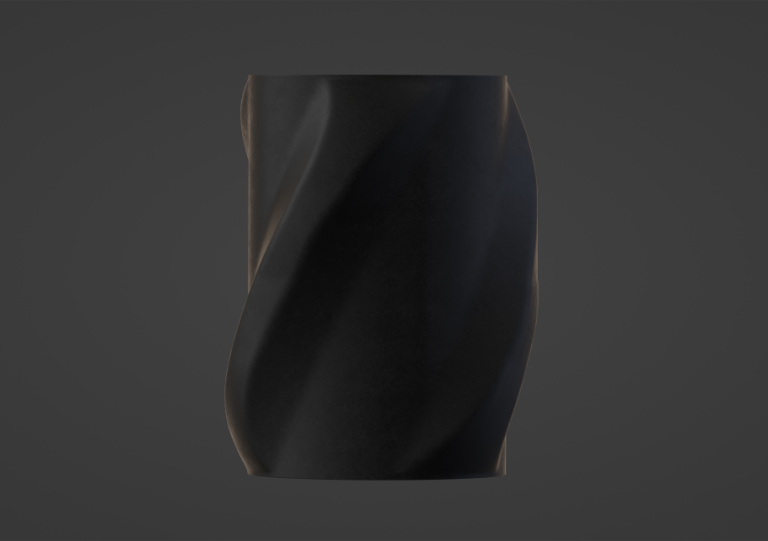

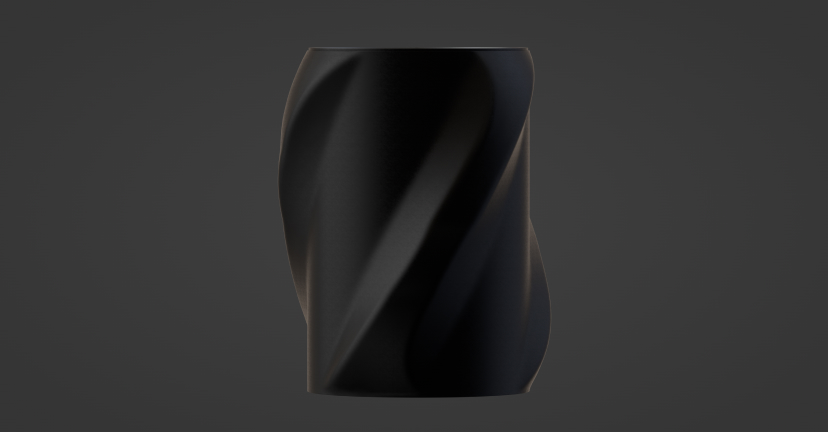

The innovative third generation GJS hydraulic system GEN3.X was created by Powell to increase the commercial speed of well construction by running casing strings without preliminary preparation and cleaning of the wellbore.

Powered drilling solution for complicated wells with reinforced worked section.

0 %

Accident rate during well cementing and drilling

Amet minim mollit non deserunt ullamco est sit aliqua dolo.

70 %

Increasing the effectiveness of descents

Amet minim mollit non deserunt ullamco est sit aliqua dolo.

1 hours

Reamer shoe drilling time

Amet minim mollit non deserunt ullamco est sit aliqua dolo.

Powered drilling solution for complicated wells with reinforced worked section.

The main engineering challenge was a significant increase in the shoe rotation speed of more than 3500 rpm to reduce the working displacement while maintaining power and reducing the time for working out complications during running the casing string, as well as the resistance of the power section to the abrasive effect of the drilling fluid.

Specifications

Key differences for Centralisers* | 400 | 450 | 500 | 550 | 663 | 700 | 763 | 963 | 1075 | 1275 | 1338 |

|---|---|---|---|---|---|---|---|---|---|---|---|

Casing Size, in

| 4 | 4 ½ | 5 | 5 ½ | 6 ⅝

| 7

| 7 ⅝ | 9 ⅝ | 10 ¾ | 12 ¾ | 13 ⅜ |

Blade OD, mm

| 117.5 | 146.1 | 149.2 | 155.6 | 209.6 | 209.6 | 231.8 | 287.3 | 308 | 380 | 438.2 |

Borehole Size, mm

| 122-143 | 149-156 | 152-166 | 165-178 | 165-178 | 215-223 | 245-250 | 295-312 | 324-340 | 393-415 | 393-415 |

Height, mm

| 0.305 | 0.305 | 0.305 | 0.305 | 0.305 | 0.305 | 0.305 | 0.305 | 0.305 | 0.305 | 0.305 |

Tool mass, kg

| 1.1 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.5 | 4.9 | 5.7 | 6.8 | 8.5 |

Friction Coefficient | 0.08- 0.10 | 0.08- 0.10 | 0.08- 0.10 | 0.08 -0.10 | 0.08 -0.10 | 0.08 -0.10 | 0.08 -0.10 | 0.08 -0.10 | 0.08 -0.10 | 0.08 -0.10 | 0.08 -0.10 |

* Data shown is for water as flushing fluid at a flow rate of 25 liters / second

Powered drilling solution for complicated wells with reinforced worked section.

Running casing strings immediately after drilling a section without reaming the wellbore

Overcoming sludge cushions, clay swelling intervals, caverns and ledges

Rotation

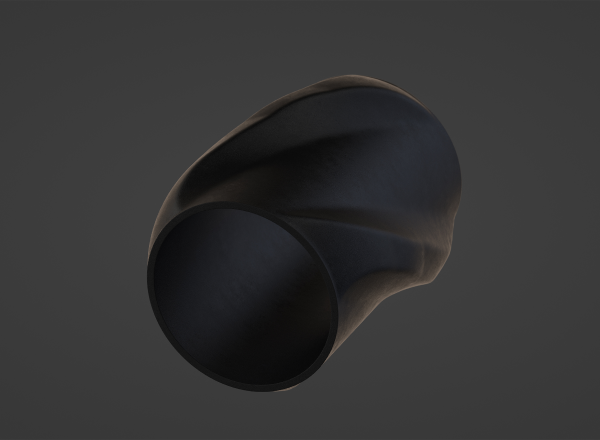

Rotation of both the shoe as a whole and separately only the front part

Sharp side

Sharp side of both the shoe as a whole and separately only the front part

Front design

Front design as a whole and separately only the front part

Frequently asked questions

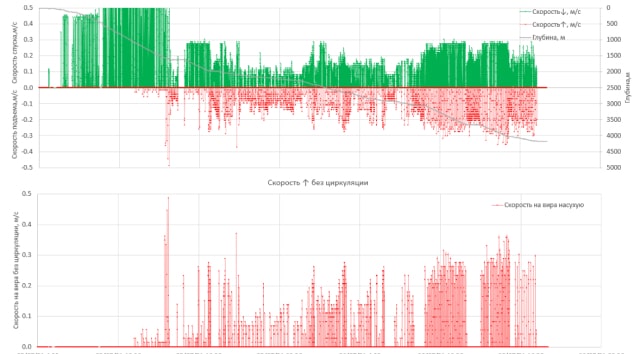

The rate of descent in the cased hole was 0.5 m / s, in the open hole – up to 0.3 m / s. When undermining a column of wedges after construction, before the start of circulation and walking, the drying speed per vira sometimes exceeded 0.2 m / s, which is unsafe from the point of view of the digital signature and could lead to collapses in the trunk.

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.